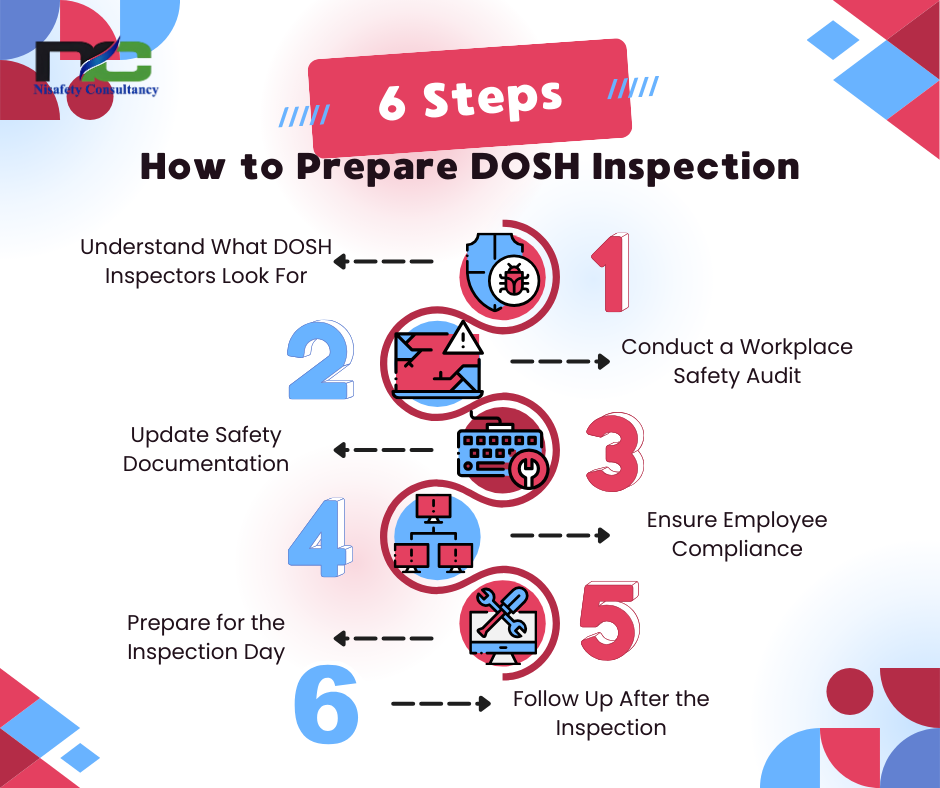

How to Prepare for a DOSH Inspection: A Step-by-Step Guide for Employers

Workplace safety is a crucial responsibility for employers, and ensuring compliance with the Department of Occupational Safety and Health (DOSH) regulations is key to maintaining a safe environment for your employees. Regular DOSH inspections are carried out to ensure that businesses are adhering to safety standards, preventing accidents, and reducing health risks. However, for many companies, preparing for a DOSH inspection can seem overwhelming.

This guide will walk you through the essential steps to prepare your workplace for a DOSH inspection, helping you stay compliant and avoid potential penalties.

Why DOSH Inspections Matter

DOSH inspections are conducted to assess whether employers are following occupational safety and health regulations. These inspections are not just about avoiding fines but also about ensuring that employees work in a safe, risk-free environment. Inspections can be routine, scheduled, or unannounced, and they typically focus on key areas such as machinery safety, chemical handling, fire safety, and employee training.

Step 1: Understand What DOSH Inspectors Look For

Before preparing for an inspection, it’s crucial to know what areas DOSH inspectors will assess. The focus of the inspection may vary depending on your industry, but here are some common areas inspectors evaluate:

- Workplace Hazards: Inspectors will check for potential hazards such as exposed electrical wiring, poorly maintained equipment, slippery floors, and other unsafe conditions.

- Machinery and Equipment Safety: DOSH inspectors will assess whether machinery and equipment are properly maintained and if safety protocols, like the use of guards, are followed.

- Chemical Handling: If your workplace uses hazardous chemicals, inspectors will check how these chemicals are stored, labeled, and handled. They may also review your Chemical Health Risk Assessment (CHRA).

- Noise Exposure: For industries exposed to high noise levels, DOSH will examine if noise control measures and audiometric testing are conducted regularly.

- Employee Training: Inspectors will review your safety training records to ensure that employees have received proper instruction on using machinery, handling chemicals, and responding to emergencies.

- Fire Safety: Fire exits, alarms, extinguishers, and fire drills are important components of a DOSH inspection.

Step 2: Conduct a Workplace Safety Audit

The best way to prepare for a DOSH inspection is by conducting your own internal safety audit. This allows you to identify potential hazards and rectify any issues before an official inspection takes place. Here’s how you can conduct an effective safety audit:

- Review Current Safety Procedures: Evaluate all safety protocols and make sure they align with DOSH standards. If you don’t have a safety management system in place, consider developing one based on DOSH’s guidelines.

- Inspect Work Areas: Conduct a walk-through of your workplace to identify any safety hazards, such as obstructed pathways, improperly stored chemicals, or malfunctioning equipment.

- Assess Risk Areas: Focus on high-risk areas such as construction zones, machinery rooms, and chemical storage areas. Check that safety equipment like guards, barriers, and PPE (Personal Protective Equipment) is being used correctly.

- Review Incident Reports: Examine past workplace accident reports to identify recurring safety issues. This can help you address underlying problems before a DOSH inspection.

Step 3: Update Safety Documentation

DOSH inspectors will review your workplace safety documentation, so it’s important to ensure that all records are up to date and compliant with regulations. Key documents to have ready include:

- Safety and Health Policy: Every company should have a documented safety and health policy outlining the responsibilities of employers and employees to maintain a safe working environment.

- Chemical Health Risk Assessment (CHRA): If your workplace involves handling hazardous chemicals, make sure your CHRA is up to date and that proper control measures are in place.

- Training Records: Keep detailed records of employee safety training sessions, including the names of attendees, the topics covered, and dates of completion.

- Machine Maintenance Logs: Ensure that you have records of routine machinery maintenance and safety checks to show that equipment is regularly inspected.

- Accident and Incident Reports: Keep all accident and incident reports easily accessible in case an inspector requests to review them.

Step 4: Ensure Employee Compliance

One of the key areas DOSH inspectors evaluate is whether employees are aware of and following safety procedures. It’s essential to make sure that your workforce is fully trained and compliant. Here’s what to focus on:

- Regular Safety Training: Ensure that all employees, including new hires, undergo regular safety training sessions covering the specific risks associated with their roles. Training topics can include equipment handling, chemical safety, fire safety, and emergency response.

- Provide Personal Protective Equipment (PPE): Make sure that all employees have access to appropriate PPE, such as helmets, gloves, masks, or ear protection, and that they are using it correctly.

- Display Safety Signage: Place clear and visible safety signage around high-risk areas to remind employees of safety protocols, such as wearing protective gear or proper handling techniques.

- Encourage Reporting of Hazards: Create a system where employees can easily report potential hazards or unsafe practices. Encourage open communication about safety concerns without fear of retaliation.

Step 5: Prepare for the Inspection Day

When the day of the DOSH inspection arrives, it’s important to be organized and cooperative. Here’s how you can make the process go smoothly:

- Assign a Point of Contact: Designate a safety officer or supervisor who will accompany the DOSH inspector during the walk-through. This person should be familiar with all safety protocols, documentation, and potential risk areas.

- Be Transparent: Cooperate fully with the inspector, answering any questions they have and providing access to all areas and documents. Avoid trying to hide issues, as this can lead to penalties.

- Correct Issues on the Spot: If the inspector identifies any minor safety violations, address them immediately to demonstrate your commitment to safety compliance.

Step 6: Follow Up After the Inspection

After the DOSH inspection, the inspector may provide feedback on areas that need improvement. Take their recommendations seriously and implement corrective actions as soon as possible. This can help you avoid future violations and maintain a safe working environment.If you receive a citation or notice of non-compliance, work quickly to address the issues. Make sure to submit proof of corrective actions to DOSH within the specified time frame.

Conclusion

Preparing for a DOSH inspection doesn’t have to be a daunting task. By conducting regular safety audits, maintaining up-to-date documentation, and ensuring employee compliance, you can create a safe workplace that not only meets DOSH regulations but also promotes a culture of safety. A proactive approach to workplace safety will not only help you pass inspections with ease but also protect your employees and your business in the long run.